The XM200C 3D metal printer is making waves in the industry, establishing a new level of price and performance. The printer deploys fiber laser-based powder-bed fusion technology by selectively fusing thin layers of metal powder to create parts directly from a 3D-CAD model. Powered by our patented Xact Core™ high-speed gantry system, the XM200C continues to revolutionize metal 3D printing.

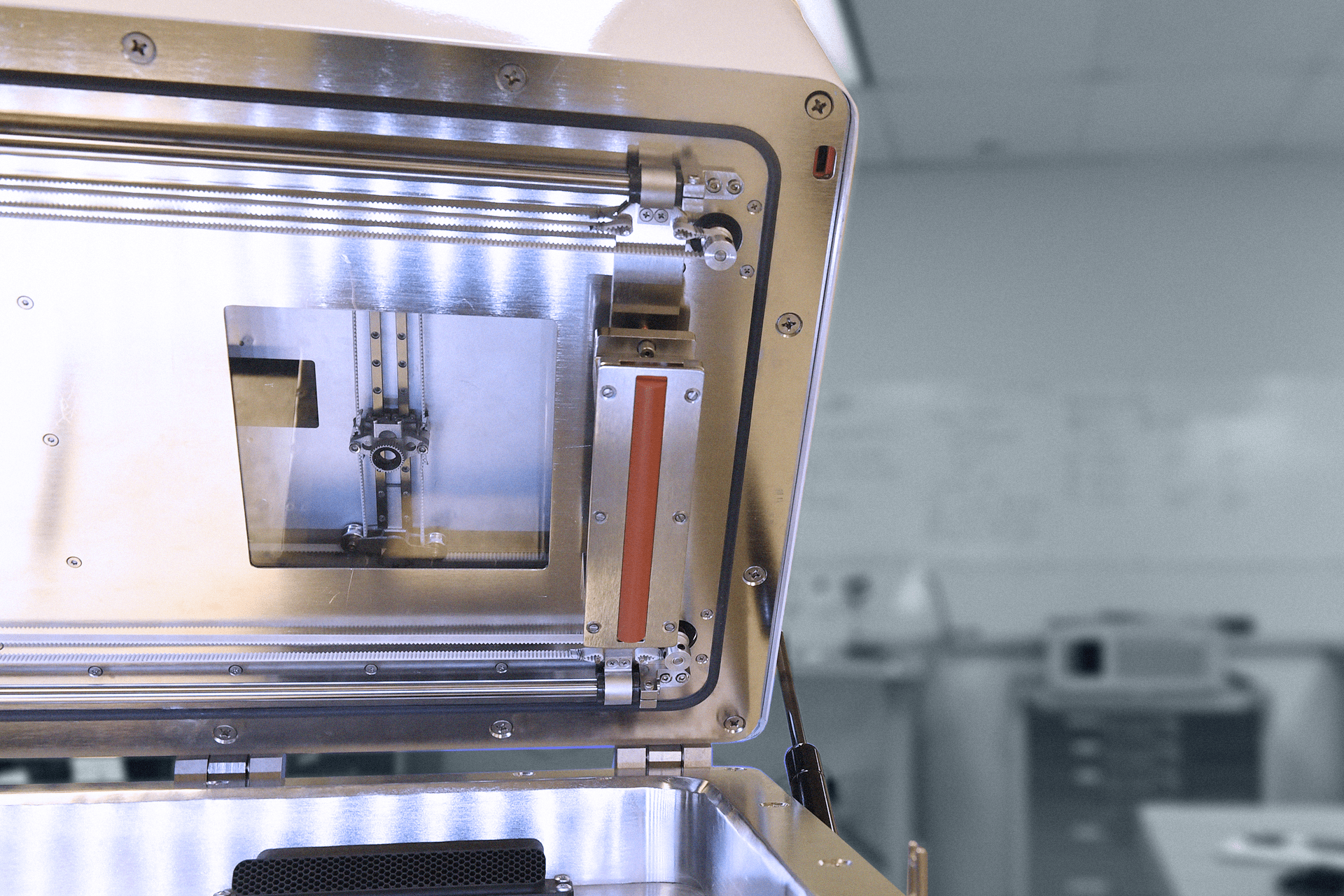

Making quality metal printing accessible requires innovation. Xact Metal’s printing technology is built on the patent-pending Xact Core, a high-speed gantry system platform that allows light, simple mirrors to move quickly and consistently above the powder bed on an X-Y axis.

Recoater performance can directly affect the quality of your build. Our patented recoater design offers a variety of benefits.

The modern, interactive graphic user interface (GUI) for the Xact Metal printers makes loading files, setting up builds and monitoring the build process quick and easy.