Xact Metal’s XM200G 3D printers provide a high-performing and affordable solution to dental labs around the world.

Utilizing single- or dual-laser options, the printer’s large 150 mm x 150 mm build area; 100, 200 or 400W fiber laser options; fast and precise galvanometer mirrors; high-quality F-Theta lens optics; and dental-specific parameters at 50 µm laser spot size and 20 µm build layers, or 100 µm laser spot size and 30 µm build layers, the XM200G family is ideally suited for metal dental applications, including:

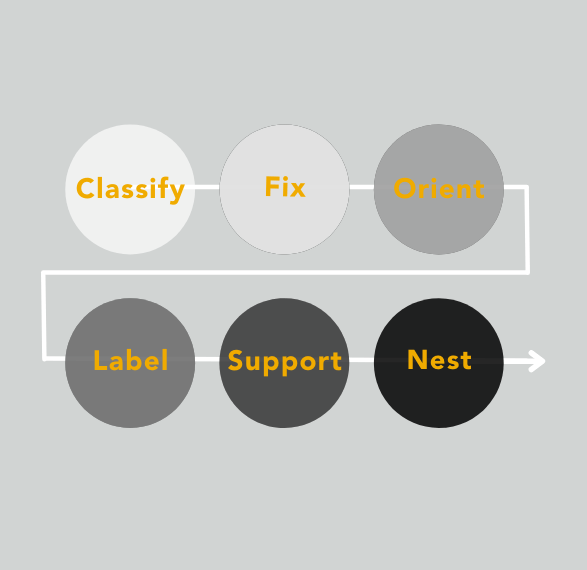

The Materialise Pre-Print Dental Module provides a dental-specific workflow that allows for classification, error repair, print positioning, part labeling, optimized support structures, and part nesting to achieve top print speed and quality. Crowns, bridges, partial dentures, and other dental parts can easily and quickly be prepared for printing.

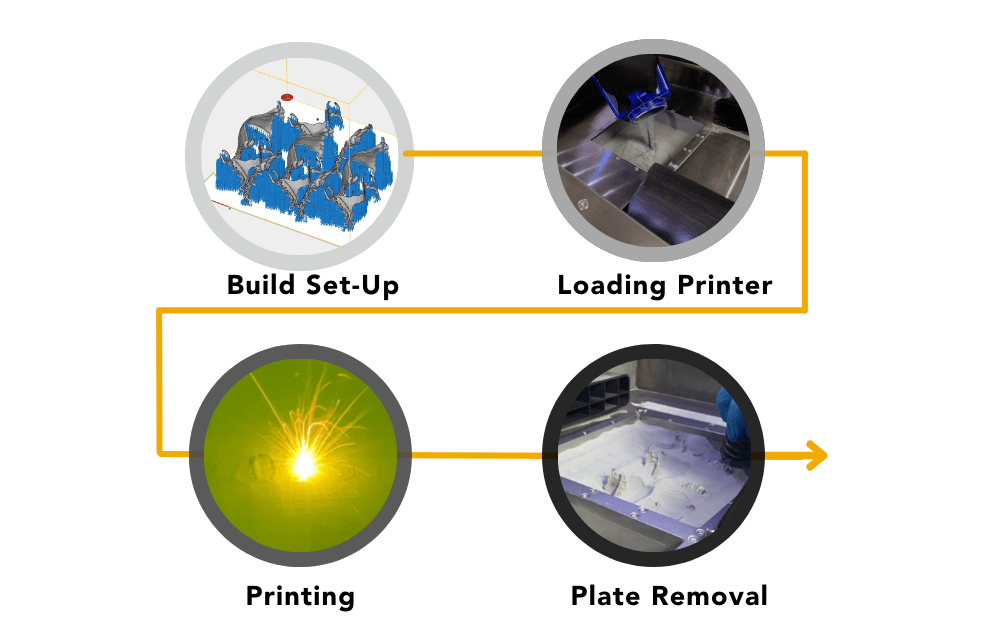

Fully integrated into Materialise Magics Print for Xact Metal, the workflow provides an intuitive software that facilitates the 3D printing process. The integrated solution includes build preparation tools, the support generation module, and the build processor. Together, these components allow the customer to repair and edit files, prepare the build platform, and generate slices easily and quickly.

Image courtesy of Bego Medical

The fit of a dental component comes down to the preference of the dentist and their patient. Achieving this subjective “sweet spot” can take multiple rounds of trial and error. Using the dental module by Materialise we can easily produce multiple variants of the component in a single print, saving the patient trips to the office and time for the dentist.