With a desire to enable manufacturers to experience the benefits of high-quality 3D metal printing at the best price possible, Xact Metal™ aims to change the perception that metal additive manufacturing is only for capital-rich companies.

We’re proud of our extensive network of sales partners that support our customers locally, from the initial application discussions to post-installation services.

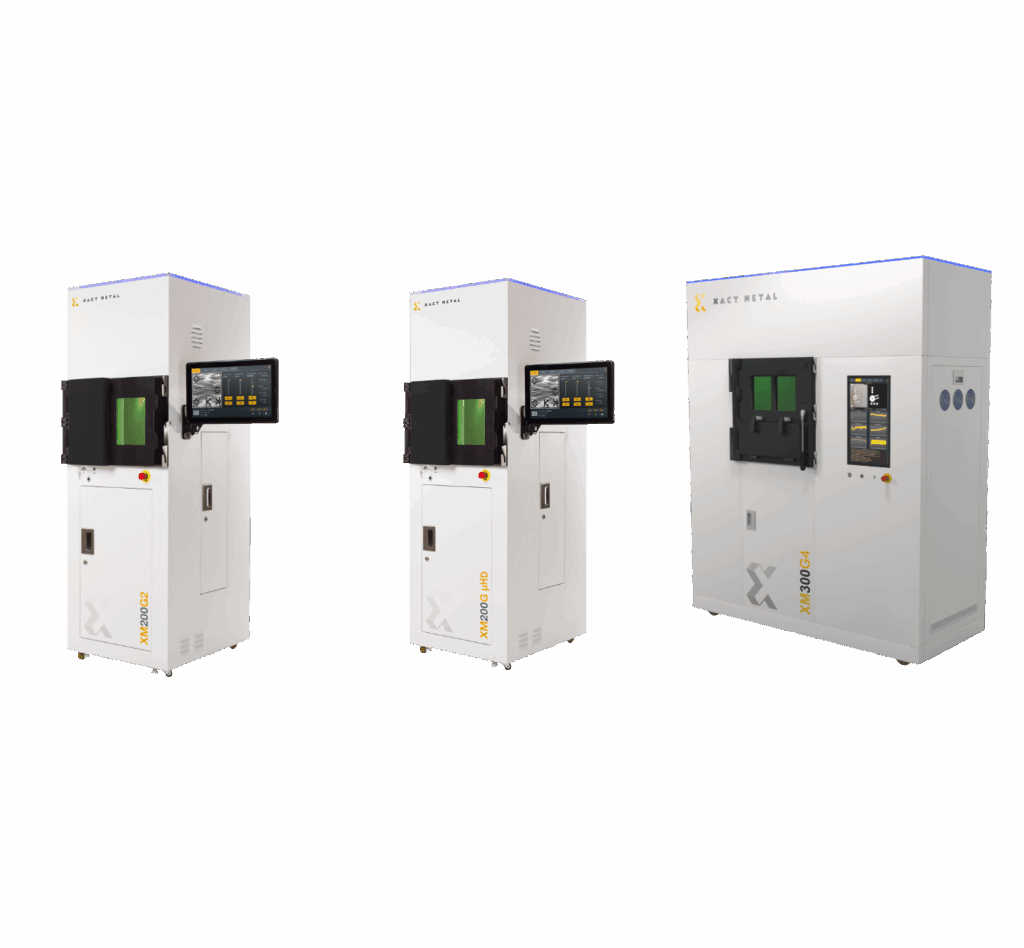

XM200G

The XM200G single- or dual-laser printer series meets demands of high-performance use cases where print speed, part quality, and affordable price is essential.

XM200G µHD

The XM200G µHD printer is suitable for printing of micro sizes and smoother surfaces required in micro applications like electronics, micro mechanics, antennas and waveguides, defense and medical devices.

XM300G

The XM300G, currently in development, offers an expanded print area for larger, industrial metal powder-bed fusion applications that need prototyping, tooling capabilities, or low-volume manufacturing.

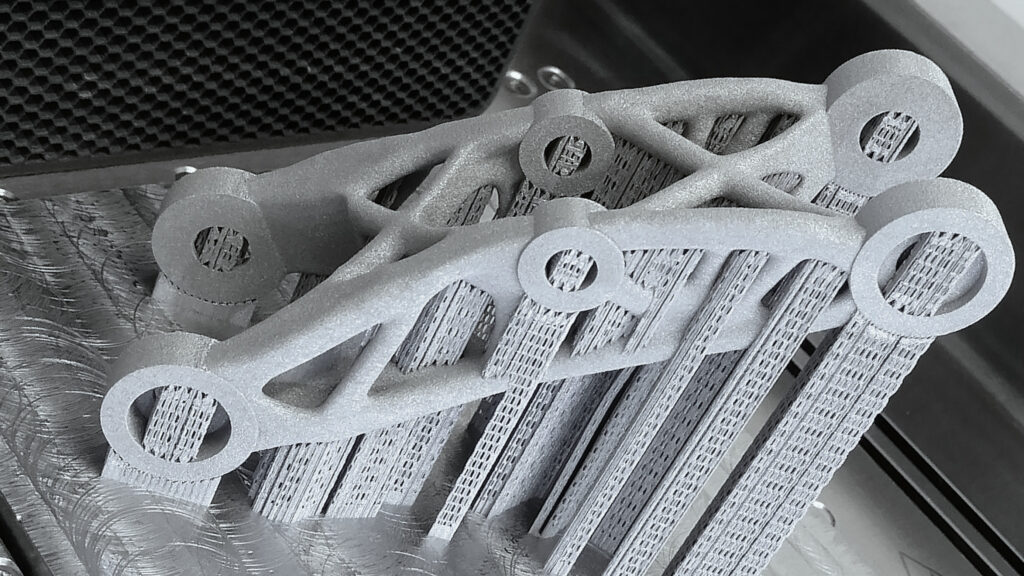

Xact Metal partners with leading material producers to offer high quality, certified and proven materials, including stainless and tool steels, super alloys, copper, titanium and aluminum.

Xact Metal partners with leaders in the industry to provide software solutions that are intuitive and modern, allowing for simple machine setup, control and monitoring.

Together with our sales partners, our services include local customer support, preventive maintenance, spare parts and powder, and more.

The wait is over! #SHOTShow 2026 is almost here. We’ll be on the floor at booth 51026. Let’s talk. pic.twitter.com/GoUCY3WU2d

— Xact Metal (@XactMetal) January 15, 2026

Exciting news ahead of #Formnext! We are introducing two new metal powders: Sandvik Osprey® MAR 55 tool steel and Equispheres NExP-1 non-reactive aluminum powder. Plus, we are launching the #XM200GµHD and reaffirming our development efforts on the #XM300G mid-size metal printer. pic.twitter.com/3ofNWjhLvs

— Xact Metal (@XactMetal) November 17, 2025

Congratulations to Lucio Ferranti and the entire Energy Group in reaching their 30th year anniversary. Over this time, they have become a leading company in Italy 🇮🇹 helping customers in their journey to adopt #3DPrinting. We are proud of our @XactMetal partnership with them. pic.twitter.com/p7H5w28C3c

— Xact Metal (@XactMetal) November 13, 2025

Case Study: K-Rain achieves 20% cycle time reduction by using innovated sprinkler head mold insert! Partnering with Zero Tolerance, they switched to @XactMetal‘s printing technology and used @uddeholm #Corrax tool steel to deliver durable inserts. More at https://t.co/6OCKrrehab. pic.twitter.com/DPPzRRBxSM

— Xact Metal (@XactMetal) October 13, 2025

Double the laser, double the speed.

— Xact Metal (@XactMetal) October 30, 2025

Our XM200G printer family comes with the option of one or two lasers, giving customer the ability to increase print speed to meet production needs.

Learn more at https://t.co/CF0qsC6Xii.#MetalAM #Metal3DPrinting #AdditiveManufacturing. pic.twitter.com/D94I3UYN9D

Join us in two weeks at Formnext in Germany 🇩🇪. Come learn about our exciting new developments and talk about #metalAM.

— Xact Metal (@XactMetal) November 6, 2025

Meet us at booth 12,0 C59.#3dprinting #additivemanufacturing pic.twitter.com/rha2y1CI0o

We’re excited to see our double digit growth continue in 2Q and 3Q 2025 and to expand our commercial sales team. Read more at https://t.co/Pet3GECGSF. pic.twitter.com/H759qHB4kH

— Xact Metal (@XactMetal) October 10, 2025

We had a great conversation with voestalpine on the latest in #metalAM materials and developments for injection molding and high-pressure die casting at K – The World's No.1 Trade Fair for Plastics and Rubber.#additivemanufacturing #metal3dprinting #plastics #moldmaking pic.twitter.com/7j3cuDPZut

— Xact Metal (@XactMetal) October 15, 2025

Join us in celebrating our 8th #anniversary!!! 🎉🎈🥳 pic.twitter.com/tkwVOMPXiE

— Xact Metal (@XactMetal) March 13, 2025

Case Studies

News