Up In Smoke

In 1980, a young and enthusiastic man named Tomme acquired a 1966 Chevrolet Impala after the vehicle sustained damage from a fire. The interior was damaged, and the dashboard had taken a beating, but the car still had life in it and Tomme was determined to restore it. There were many improvements needed to be made to the car to bring it back to a drivable state, but with time and much care from Tomme, the car began to resemble the original model.

Once the car had been brought back to its original state, Tomme began making custom upgrades to the vehicle. In 2014, he had the idea to add more eccentric exhaust pipes, but manufacturing custom metal is a costly process that requires heavy duty equipment. While Tomme was deeply invested in this project, it was not viable to invest so heavily into a hobby.

The fire that damaged the ’66 Impala began under the hood, spreading through the electrical systems and destroying the instrumentation in the front seat of the car. The hood plate lost shape from the heat and will need to be replaced, as well the interior leather which sustained damage from the smoke.

The damage was considerable, but not fatal. Under the hood, large steel components survived the heat and inside the tailgate remains in good condition. With low mileage and a story to tell, this car was worth repairing.

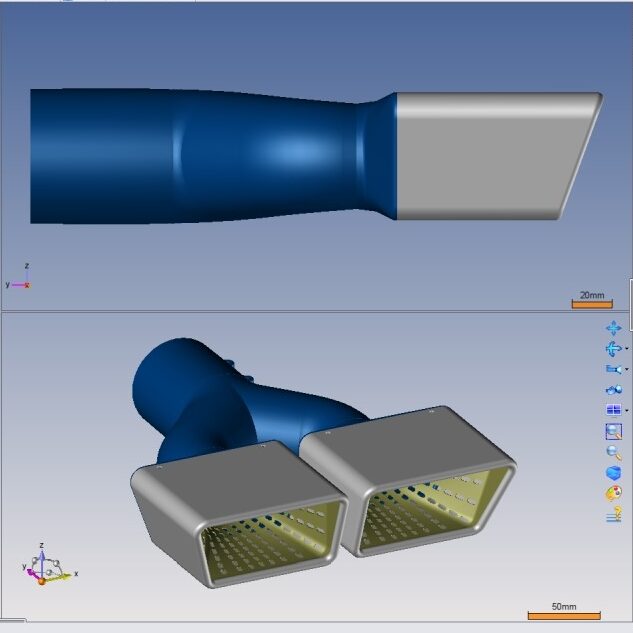

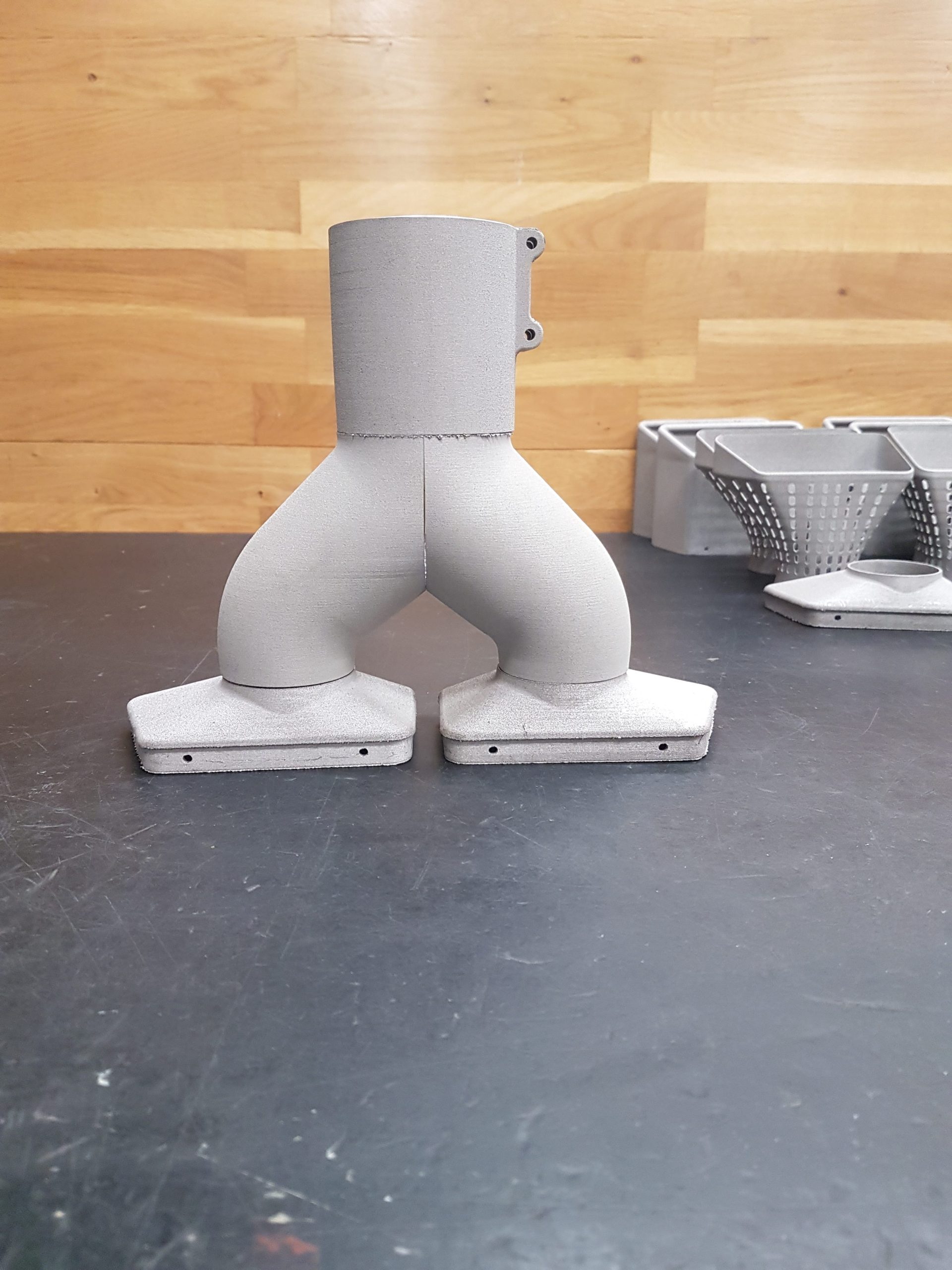

In March of 2022, an opportunity arose to finally build this custom tailpipe, and Tomme took it. The project had been on an indefinite hold because it was impossible for Tomme to manufacture the pipes in stainless steel until the XM200C, a metal 3D printer by Xact Metal, was installed at the Protech office, his workplace in Sweden. With this machine at his disposal, this fantastical idea was realized eight years later. Tomme hoped to retain the classic feel of the car, while adding a modern flair. He began considering different designs and testing a few models. The design he landed on has rectangular tailpipes, with the outer sides and rear edges angled, mimicking the Impala’s rear bumper. He then designed the 3D models in a software program called TopSolid. They became the basis for the metal parts later 3D printed in the XM200C.

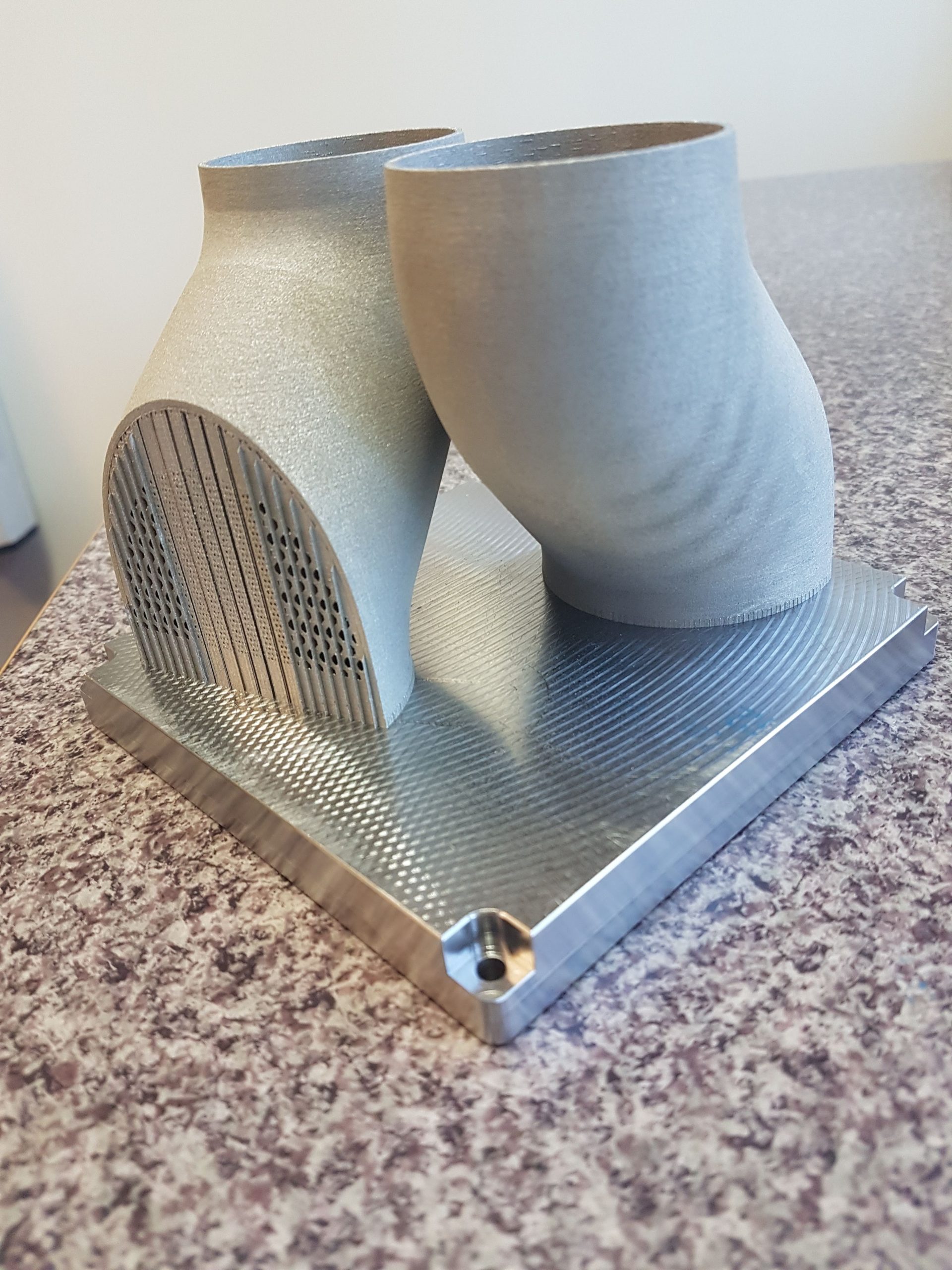

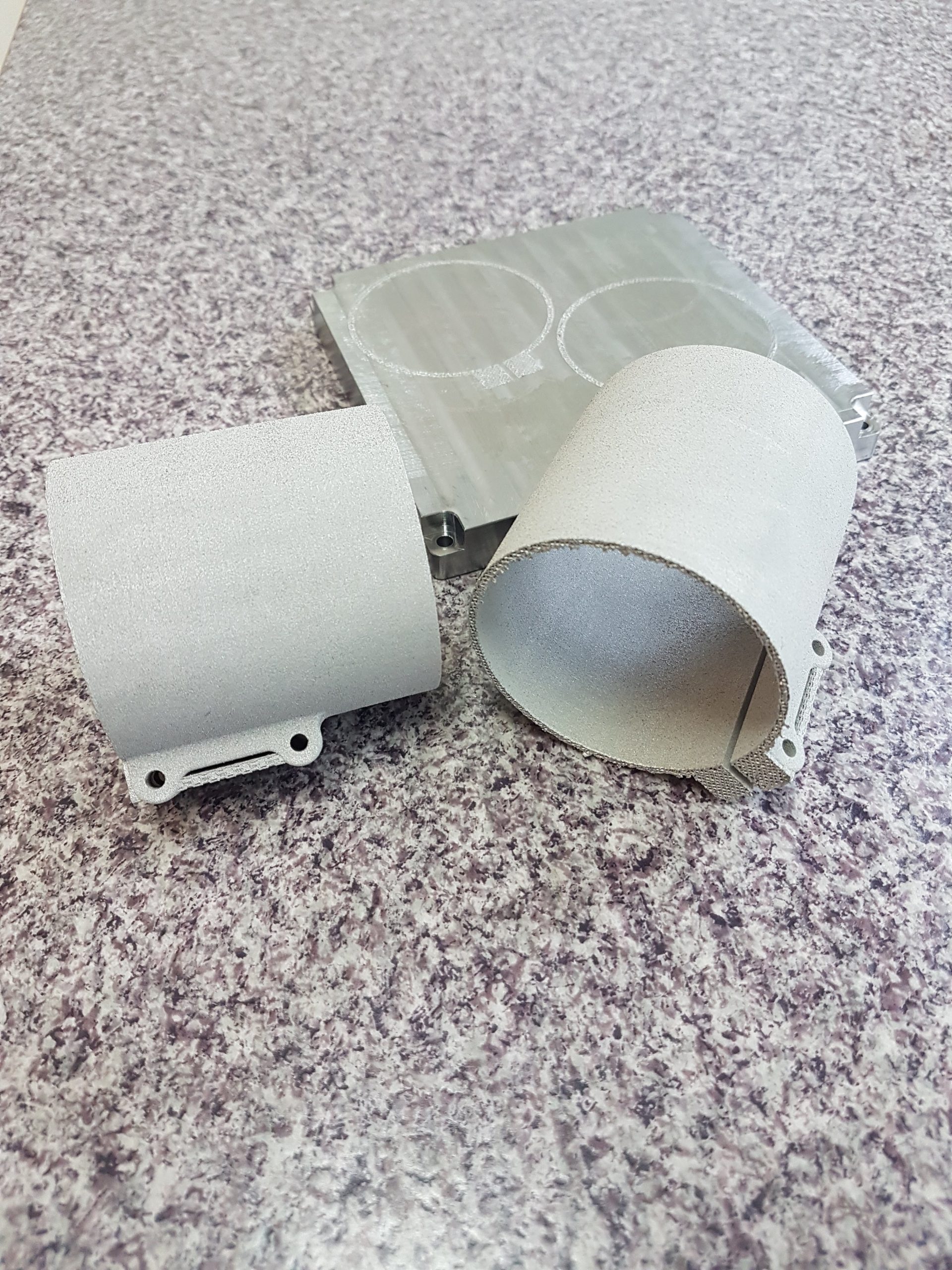

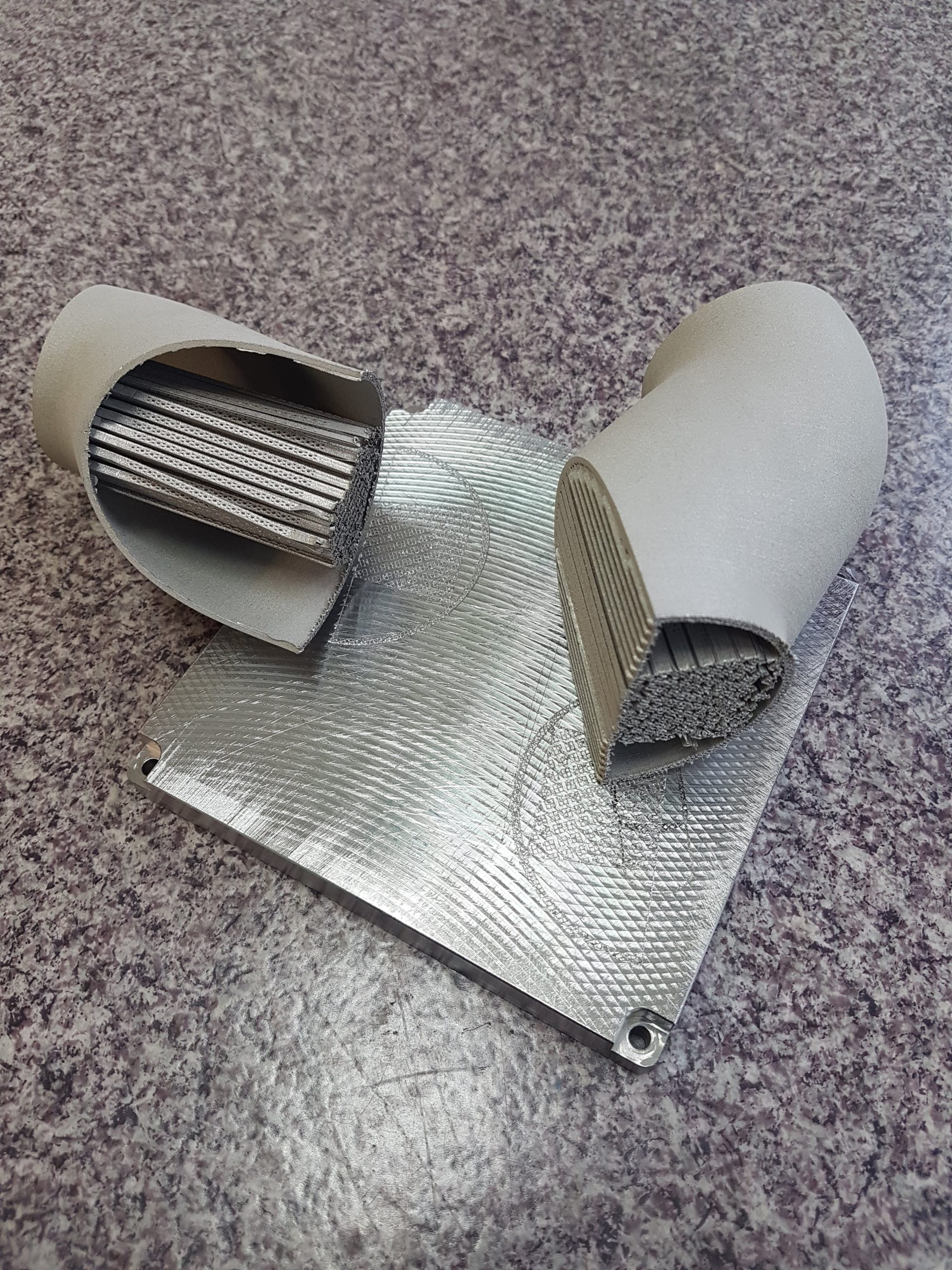

In order to produce the final product, the tailpipe design had to be a multi-part assembly. A Y-Pipe is clamped directly to the existing tailpipe and on each arm is a perforated insert. This insert is held in place by a rectangular cover that screws into an arm of the Y-Pipe. These parts are too large to be printed as a complete set in the XM200C, so they are welded together afterwards.

The car has a V8 engine with dual exhaust pipes, so this design will make it appear as though there are four total exhausts. Prior to building the initial prototype, some details were printed in stainless steel to test the functionality of the clamp and to assess the finish of sanding and polishing the ends. Once these parts were validated, Tomme got to printing.

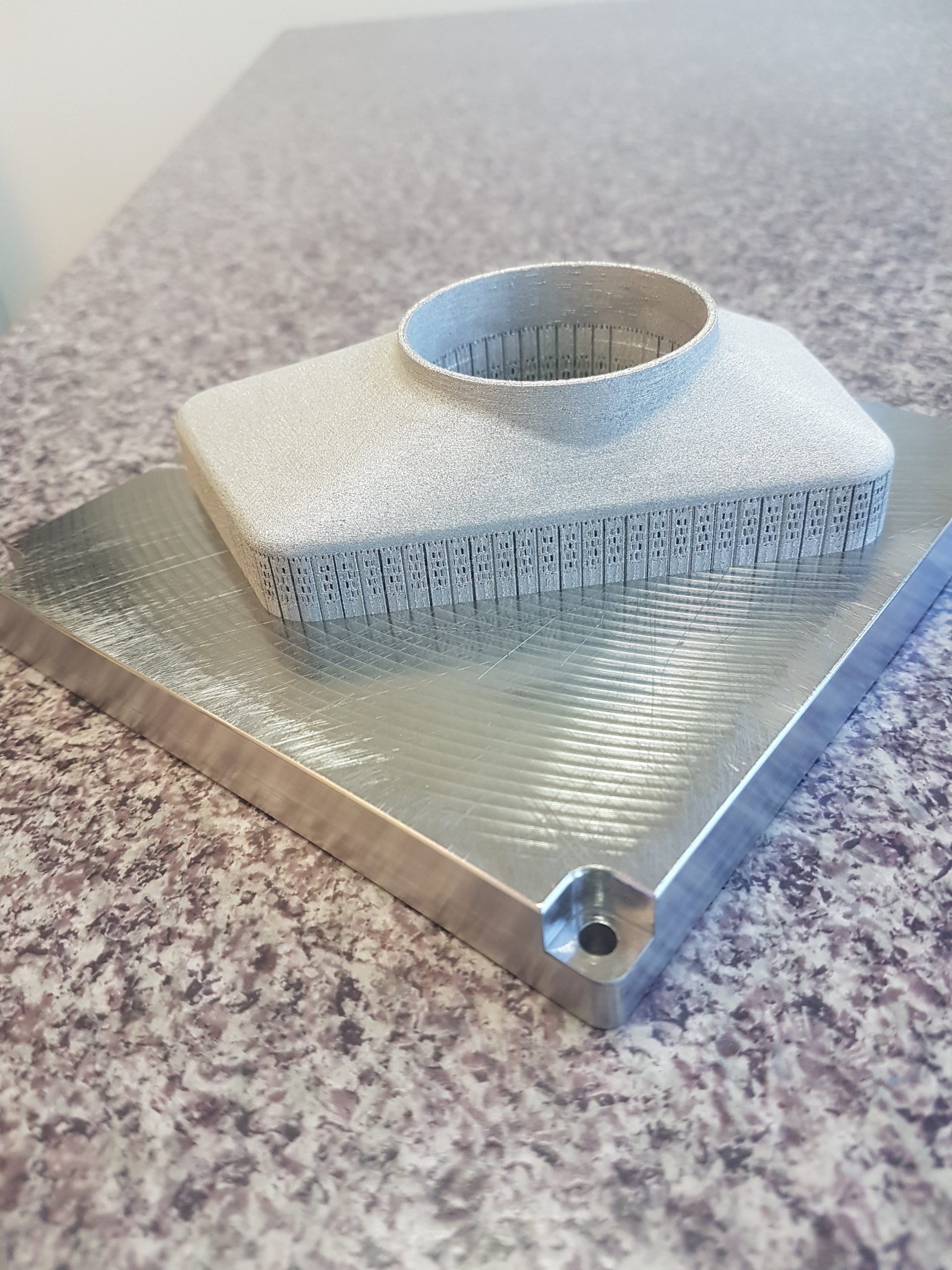

In the XM200C, parts are built upwards using a high energy laser that traces a geometry in a metal powder, layer by layer, to form the part. When the part is complete, the geometries are welded directly to the plate. The excess powder is removed and recycled, the part is cut off the plate and the support material is removed. This can be done by hand using pliers. These parts could be functional directly after printing, as they are fully dense as-printed. However, in the interest of aesthetics, all parts except the inserts, are sanded and polished. Specifically the end pipe, which is the most visible component.

The Impala has been featured in automotive magazines and it has also been entered into multiple car shows across Europe. Thanks to the care and dedication from Tomme, the 1966 Chevy Impala was turned from a fire wreck into a vehicle to be admired. The classic car has been a long-term project for Tomme, spanning many years. The project has introduced him to new technologies, new people, and even won him a few awards along the way.

More details about Tomme’s work are available on his blog.

As-Printed Components

Plate Removal Using Standard Band Saw

Support Removal

Welding Together Segments

Installation