The pressure to reduce cost is plaguing manufacturers across industries. There is a need to speed up development while also improving part quality. The tooling used to support manufacturing lends to these issues, but is often overlooked.

The truth is, metal 3d printing can speed up product development, raising profitability, especially when tackling complex geometries including internal features and channels. As-printed parts have a high-density (99.5% +) and have tolerances tight enough to bypass the soft machining process altogether, moving straight to heat treatment for required hardness.

The way we see it, additive manufacturing is another tool in your toolbox with a range of capabilities and the potential to improve your current way of doing things. Our mission is simply to help molders and mold makers use this technology to:

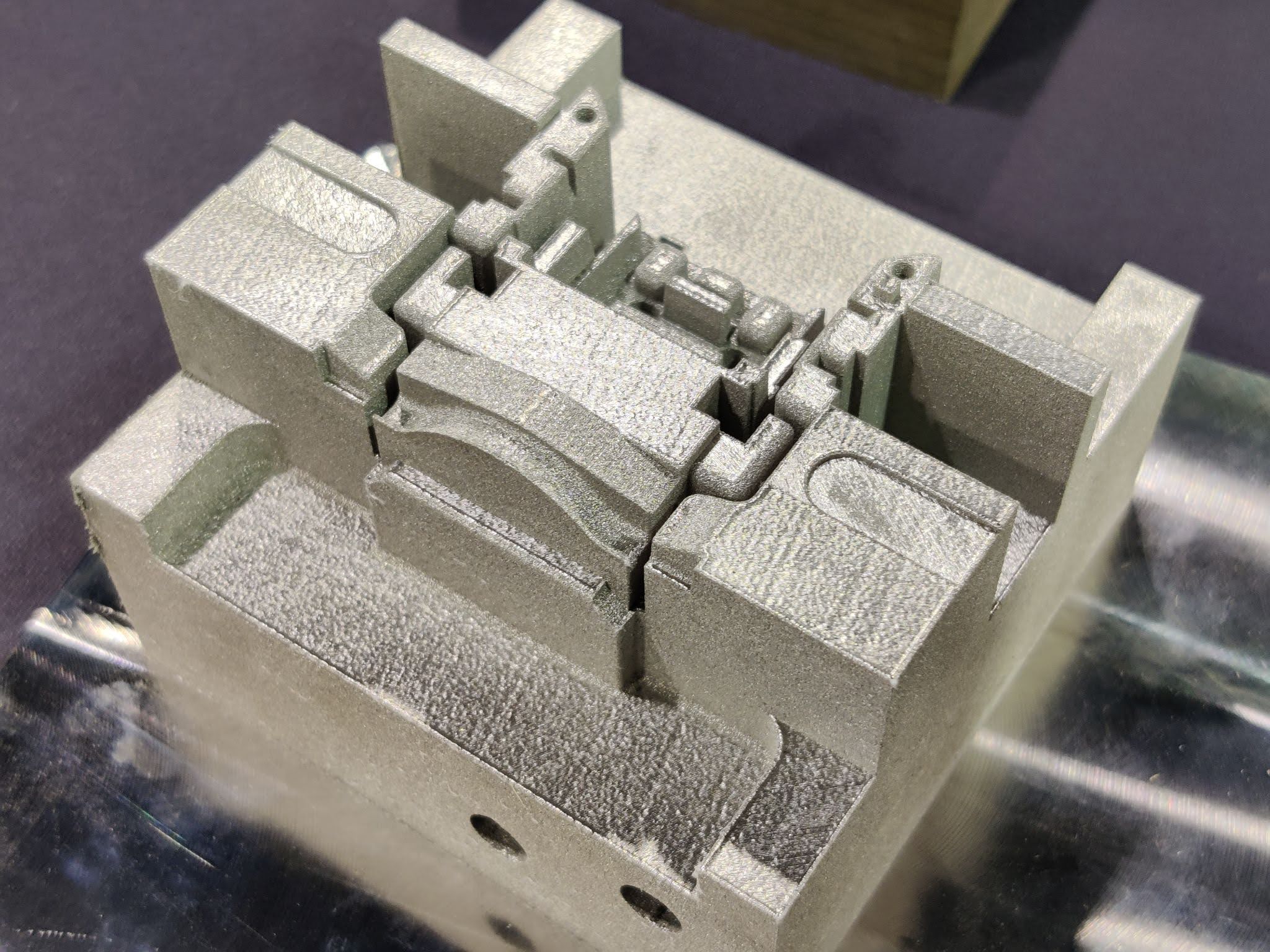

The use of additive for tooling components can lend a hand in solving problems because additive manufacturing allows part design to be based on the desired function, rather than standard limitations of part production.

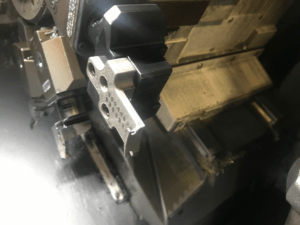

This chip sweeper was able to eliminate several minutes, each hour, of production line stoppage for debris to be manually removed. This new design was possible because of additive, including a small hook to pull out the debris from the part and high pressure coolant channels to wash away remaining debris. Downtime was greatly reduced and additional chip sweepers were installed across six different lines.

These work holding devices, which can only be produced with additive manufacturing, replaced the previous design which required a multi-part assembly of springs and clamps. By designing for additive manufacturing, gravity can be employed to hold the device in place on a direct inner negative. This one change has saved thousands of dollars in design and machine time.

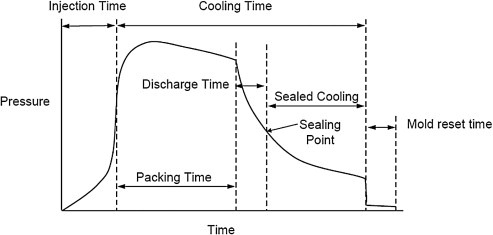

Injection molding is a great application for additive manufacturing because with simple design modification, often of an existing part, conformal cooling channels can be added, therefore reducing cycle time. Considering 80% of typical cycle time consists of cooling, the impacts can be large.

Whilst still young in adoption, metal 3d printing can drastically lower labor cost associated with parts at the beginning of their manufacturing journey. If a new part is needed or a part requires repair, it may only take a few hours of the operator’s time to prepare and run the print, leaving them free to work on other projects during print time. Once completed, builds are immediately ready for heat treatment, omitting the soft milling process. This post-processing is much less labor intensive compared to what is required for traditional manufacturing. Thus, labor hours can be repurposed elsewhere, resulting in a more efficient manufacturing facility.

Thanks to metal 3d printing, projects that would have been put on the back burner can be taken on. Without the need for continuous oversight by an operator, R&D projects can take place in the background without occupying hours of the operators time. This provides an opportunity for trials to be run without interrupting daily operations. And who knows, one of those tests may be the next great innovation!