Metal Powder-Bed Fusion—also known as Selective Laser Melting or Direct Metal Laser Sintering—is an Additive Manufacturing process using a laser to melt consecutive layers on a metal powder-bed. The powder fuses into the finished dimensional part, incorporating complex internal and external geometries.

Removal of part from build plate with wire EDM, bandsaw, or flush cutting tool

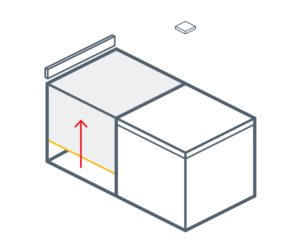

Feed cylinder increments up placing powder in front of the recoater.

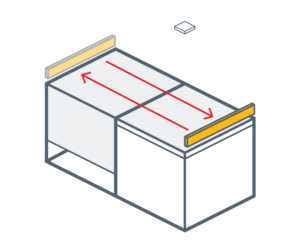

Recoater moves across the feed cylinder delivering powder to the build cylinder.

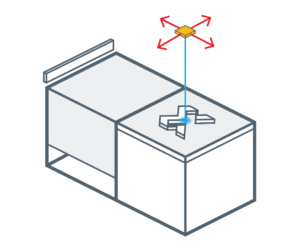

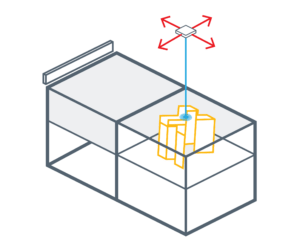

Laser fuses the cross section of the part.

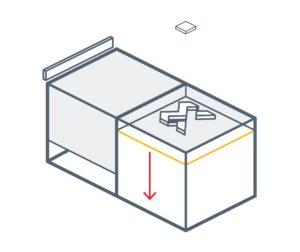

Build cylinder increments down one thickness layer.

The process is repeated until the volume of the part is fully built.

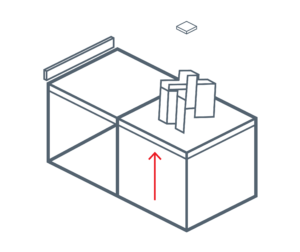

The build cylinder raises up and the build plate is removed.