The way we see it, additive manufacturing is another tool in your toolbox with a range of capabilities and the potential to improve your current way of doing things. Our mission is simply to help molders and mold makers use this technology to:

The partnership between Xact Metal and Uddeholm, enabling Xact Metal to offer Corrax metal powder, represents a significant advancement in the mold and tooling industry. Corrax’s unique properties, including better corrosion resistance and the ability to achieve an A1 surface finish after benching, will revolutionize the possibilities for mold making.

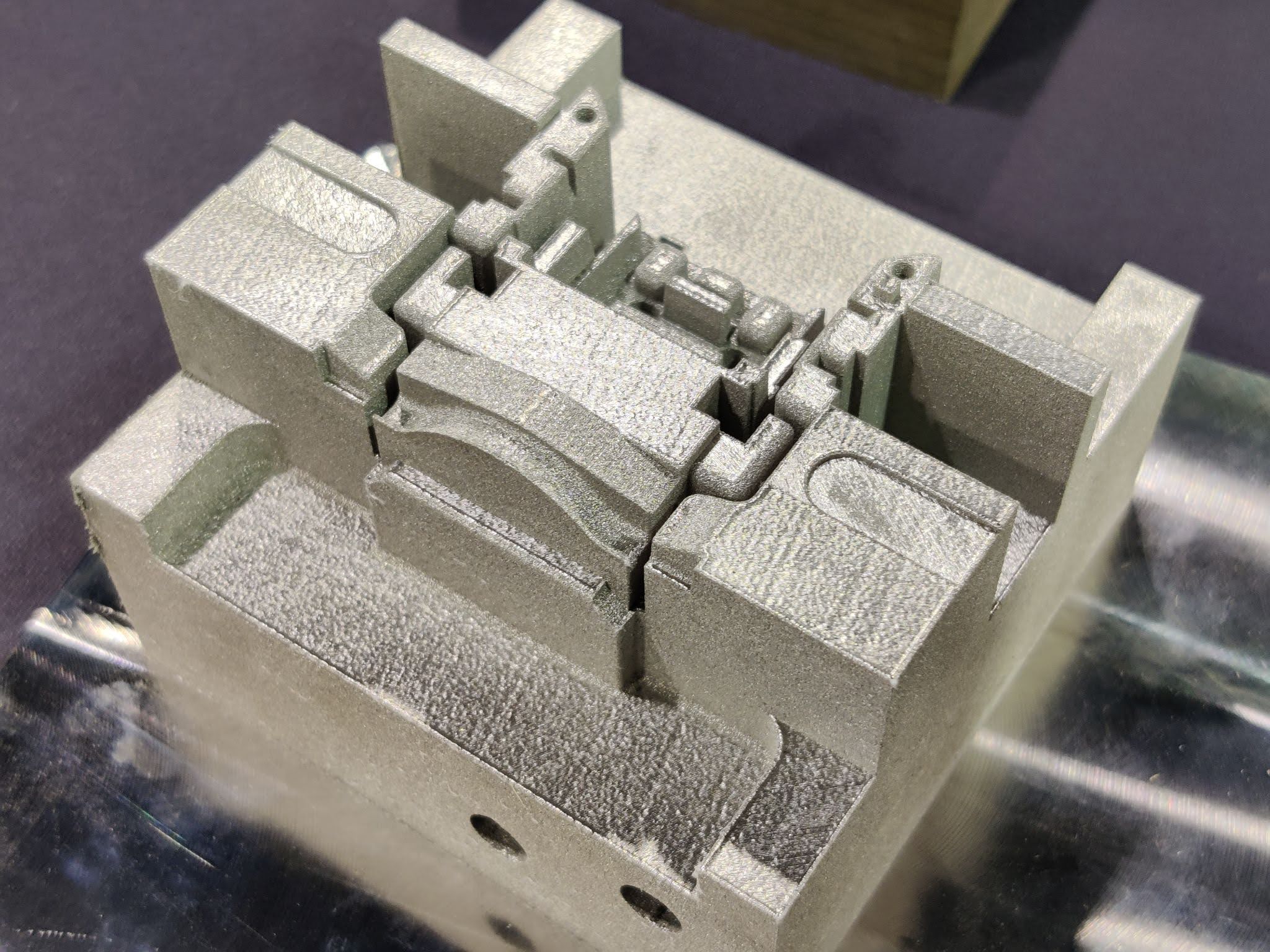

By leveraging this cutting-edge material in conjunction with Xact Metal’s accessible metal 3D printing technology, manufacturers can now produce molds with intricate designs and close-to-cavity channels for faster cooling times. This partnership not only enhances the quality and durability of molds but also streamlines the production process, ultimately driving efficiency and innovation in the mold and tooling sector.

At Xact Metal, we are immensely proud of our partnership with Uddeholm, which grants us the exclusive ability to offer their revolutionary Corrax metal powder. Uddeholm’s rich history and expertise in the steel industry bring a legacy of excellence and innovation to our collaboration. This partnership not only signifies a significant milestone in additive manufacturing but also a new era of possibilities for the mold and tooling industry, where complexity meets efficiency, and tradition meets innovation.

Over a 33-year career, Scott Kraemer has excelled in the development of complex injection multi-shot molds, tooling, and products across industries, including medical, automotive, and consumer goods. Over the past 13 years, Scott has been a trailblazer in the incorporation of additive manufacturing (3D printing) for both plastic and metal into mainstream production parts and tooling.