GHENT, Belgium, May 2, 2023 – Oqton, a software provider helping manufacturers increase innovation and efficiency by intelligently automating production, today announced it has entered a partnership with Xact Metal, a solution provider focused on enabling manufacturers to experience the benefits of high-quality 3D metal printing at the best price possible. Through this partnership, Oqton and Xact Metal are integrating their additive manufacturing (AM) solutions to deliver automation and full process control at an affordable price. This will empower a breadth of users — from entry-level engineers to skilled experts — to realize the benefits of metal AM for R&D and production applications in a variety of industries.

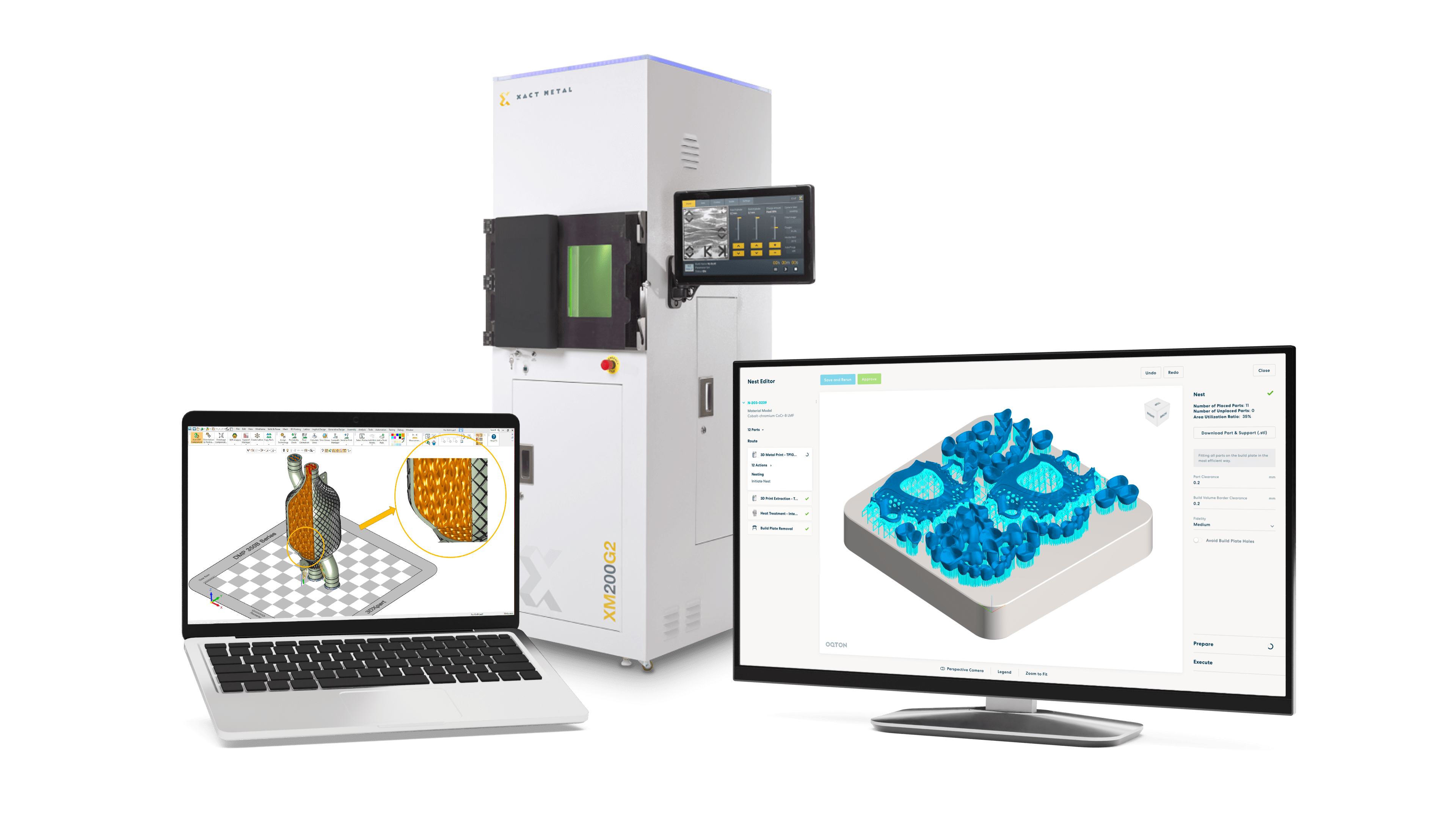

Manufacturers in industrial and healthcare markets require a scalable combination of additive manufacturing software and hardware to meet their unique business requirements and help them maintain a competitive advantage. Oqton’s partnership with Xact Metal brings together Oqton’s Manufacturing OS and 3DXpert, and Xact Metal’s portfolio of metal 3D printing technologies to create bespoke solutions for each customer’s intended use case — making them easy to adopt and implement. Benefits of each include:

As a result of this partnership, Xact Metal customers can address more applications using the in-depth features and built-in automation of Oqton’s 3DXpert and Manufacturing OS. Through the expansion of Oqton’s ecosystem on a new printing platform, the company’s customers are able to more easily adopt metal AM through a solution that meets their unique manufacturing requirements.

“The partnership we’re announcing today with Xact Metal will enable a broader range of manufacturers to embrace AM to accelerate their innovation,” said Roy Sterenthal, vice president, industrial additive, Oqton. “Our integrated solutions are bringing together the latest in AI and metal additive manufacturing to deliver a complete, cloud-accessible, automated workflow. This allows us to deliver solutions for a variety of users and manufacturers from small industrial manufacturers to dental laboratories with high-volume, AI-driven production automation.”

“We are excited to announce our partnership with Oqton,” said Juan Mario Gomez, CEO of Xact Metal. “Expanding our software options with Oqton’s solutions is the next step in our journey to expand access to metal 3D printing technology. Existing users of 3DXpert and Manufacturing OS no longer are required to learn new software to begin printing on Xact Metal printers. Oqton’s 3DXpert brings high-performing printing capabilities to our customers while Oqton’s dental software provides AI-driven proven solutions resulting in an easy-to-use workflow in dental applications.”

Manufacturers interested in taking advantage of this ground-breaking solution to transform their business can visit Oqton in booth #2435 and Xact Metal in booth #4836 at RAPID+TCT 2023 to be held May 2-4 at McCormick Place – West Building, Chicago, Illinois, or they can contact an expert via the company’s website.

Forward-Looking Statements

Certain statements made in this release that are not statements of historical or current facts are forward-looking statements. Forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company to be materially different from historical results or from any future results or projections expressed or implied by such forward-looking statements. In many cases, forward-looking statements can be identified by terms such as “believes,” “belief,” “expects,” “may,” “will,” “estimates,” “intends,” “anticipates” or “plans” or the negative of these terms or other comparable terminology. Forward-looking statements are based upon management’s beliefs, assumptions, and current expectations and may include comments as to the company’s beliefs and expectations as to future events and trends affecting its business and are necessarily subject to uncertainties, many of which are outside the control of the company. Although management believes that the expectations reflected in the forward-looking statements are reasonable, forward-looking statements are not, and should not be relied upon as a guarantee of future performance or results, nor will they necessarily prove to be accurate indications of the times at which such performance or results will be achieved. The forward-looking statements included are made only as of the date of the statement. Oqton undertakes no obligation to update or review any forward-looking statements made by management or on its behalf, whether as a result of future developments, subsequent events or circumstances or otherwise.

About Oqton

Oqton accelerates intelligent manufacturing by providing comprehensive software solutions for additive production, 3D scanning, and robotic welding — helping industrial and healthcare organizations drive innovation and efficiency. The company’s additive production software enables complete traceability and visibility across an organization, delivering AI-powered capabilities for image segmentation, additive design, build prep, MES, additive inspection, and simulation. Global manufacturers use Oqton software to automate robotic welding to increase productivity. The company’s industry-leading Geomagic suite is the foundation of 3D scanning solutions for reverse engineering and inspection applications. Oqton is supported by partnerships with machine and scanner vendors, software partners, and ERP/CAD/PLM integrations. For more information, visit www.oqton.com or LinkedIn.

About Xact Metal

At Xact Metal™ is taking the essential specs for metal 3D Printing and combining them with breakthrough technology to establish a new level of price and performance in additive manufacturing. With a desire to enable more and more designers, developers and manufacturers to experience the benefits of high-quality metal 3D printing at the best price possible, Xact Metal aims to change the perception that additive manufacturing is only for capital-rich companies. The company was founded in 2017 and is located in State College, Pennsylvania. For more information visit: www.xactmetal.com.

###