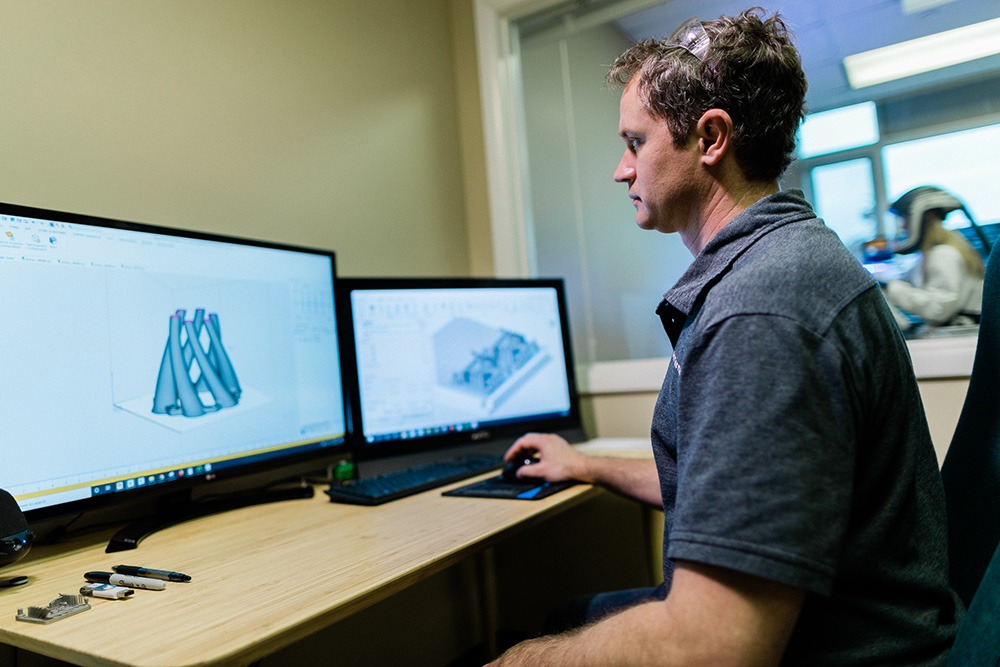

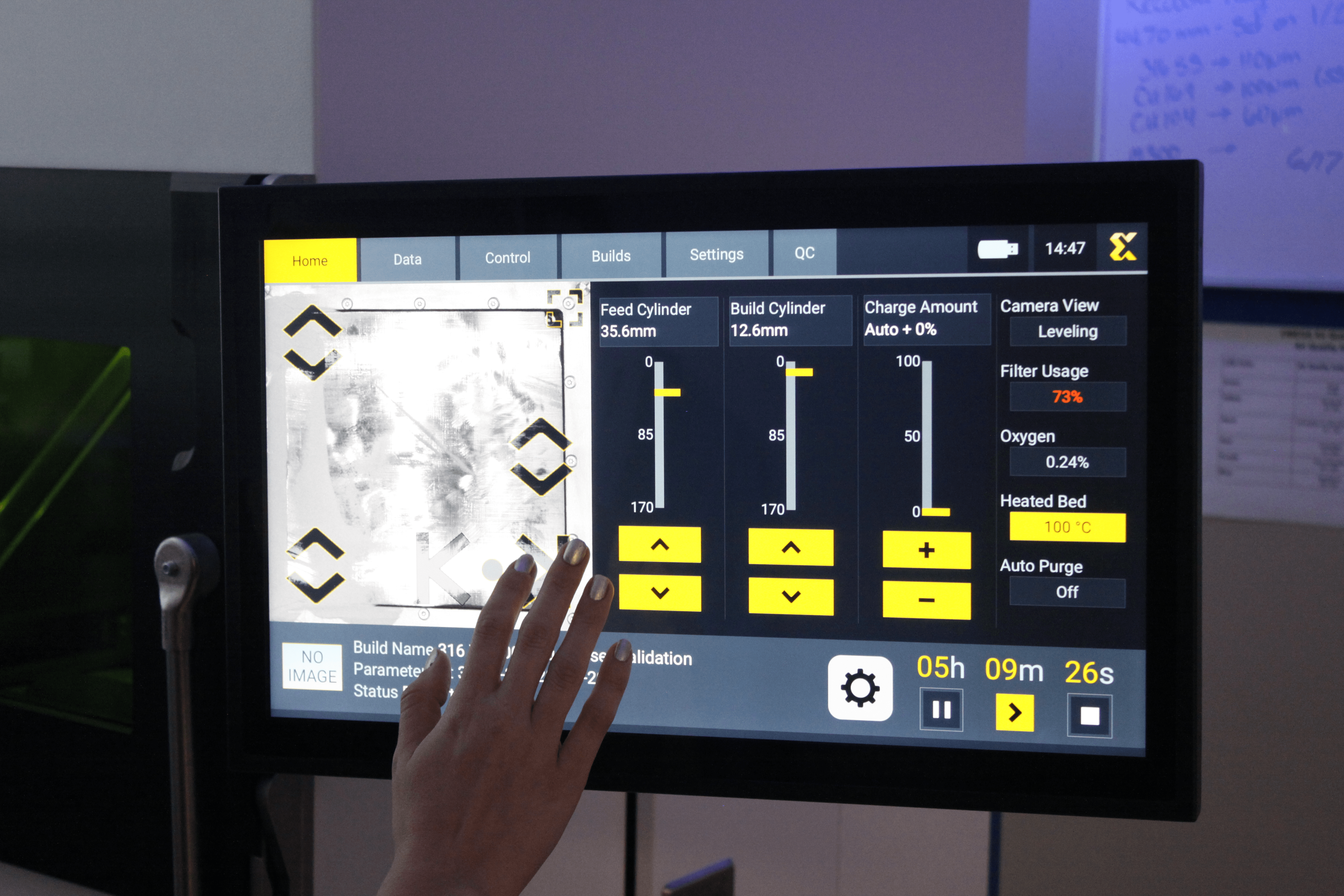

Xact Metal software is designed to be easy to use both on the printer and on the workstation.

In addition, it works seamlessly alongside other additive manufacturing software systems commonly used in the industry including Materialise Magics, Oqcam and Oqton’s 3DXpert.

Have questions on workflow? See Complete CAD-to-Part workflow outline.

The GUI (graphic user interface) for Xact Metal printers makes loading files, setting up builds and monitoring the build process quick and easy.

Materialise software tools work to manage additive manufacturing processes with efficiency and intelligence. With 30 years of additive manufacturing experience, Materialise brings together the largest group of software developers in the industry to focus on software solutions for 3D printing services.

See more at www.materialise.com

Dental Lab Software

Powered by advanced AI technology, Oqcam dental lab software automates digital production workflows for all dental applications.

Oqcam provides automated dental workflows to help meet growing production goals while significantly reducing manpower requirements. An end-to-end, integrated dental production system, Oqcam ensures full traceability to future-proof your business.

Oqcam is agnostic, replacing multiple disconnected software applications, across all of your machines.

See more at http://oqcam.com

Oqton software optimizes machine utilization by unifying engineering and production. Powered by AI technology, the neutral cloud-based Manufacturing OS provides complete traceability and visibility across an organization. In combination with Oqton’s specialized applications such as 3DXpert for design, 3D printing, and simulation, manufacturers can connect technologies and machines across multiple sites.

All-in-one additive manufacturing software, 3DEXPERT streamlines the workflow by preparing, optimizing, and 3D printing high-quality parts in record time. 3DXpert enables fast file preparation because of its superior DfAM and build prep functions which are built on an industrial CAD engine.

See more at www.oqton.com