A highly configurable combination of speed & performance at an affordable price. The XM200G printer series meets the specification demands of high-performance applications in manufacturing, research & development and other applications where print speed, part quality, and affordable price are essential.

High performance lasers, galvanometers, and optics ensure high quality as-printed parts with greater than 99.5% density to meet mechanical property requirements.

XM200G Features

The XM200G tailors to customers in product development, manufacturing and tooling, and research and workforce development. It aims to further expand the use of metal 3D printing in aerospace, automotive, general manufacturing, medical and dental, and other industries.

The XM200G configuration can be defined to meet the specific requirements of various customers.

| Feature | Options |

| Number of Lasers | 1 or 2 |

| Laser Power | 100, 200 or 400W |

| Laser Spot Size | 50 or 100 µm |

| Galvanometer | Standard, Performance, or Water Cooled |

| Material | Non-Reactive or Reactive |

| Build Cylinder Z Height | Standard (150 mm) or Extended Option (up to 290 mm) |

| Feed Cylinder Z Height | Standard (150 mm) or Extended (270 mm) |

| Power | 100-120 or 200-240 VAC single-phase power |

| Other Options | Dual Glove Box, XMini Material Development Module and Air Cooling Unit |

Increased laser power and number of lasers allow for printing of thicker layers and multiple parts, decreasing overall build times.

For example, the following are the print times to four (4) mold Inserts using Uddeholm Corrax and 100 µm laser spot size in a single print:

| Number of Lasers | Laser Power (Watts) | Print Time (Hours) | Print Time Savings vs Single Laser & 100W |

| 1 | 100 | 73 | – |

| 1 | 200 | 37 | 49% |

| 1 | 400 | 15 | 79% |

| 2 | 100 | 45 | 38% |

| 2 | 200 | 24 | 67% |

| 2 | 400 | 10 | 86% |

Installing a new technology into a facility can be a challenging and time-consuming task. Thanks to its compact size and simple set up, the XM200G can be easily installed into a facility without the need for extensive modifications. In addition, the system only requires a 100-120 or 200-240 VAC single-phase power.

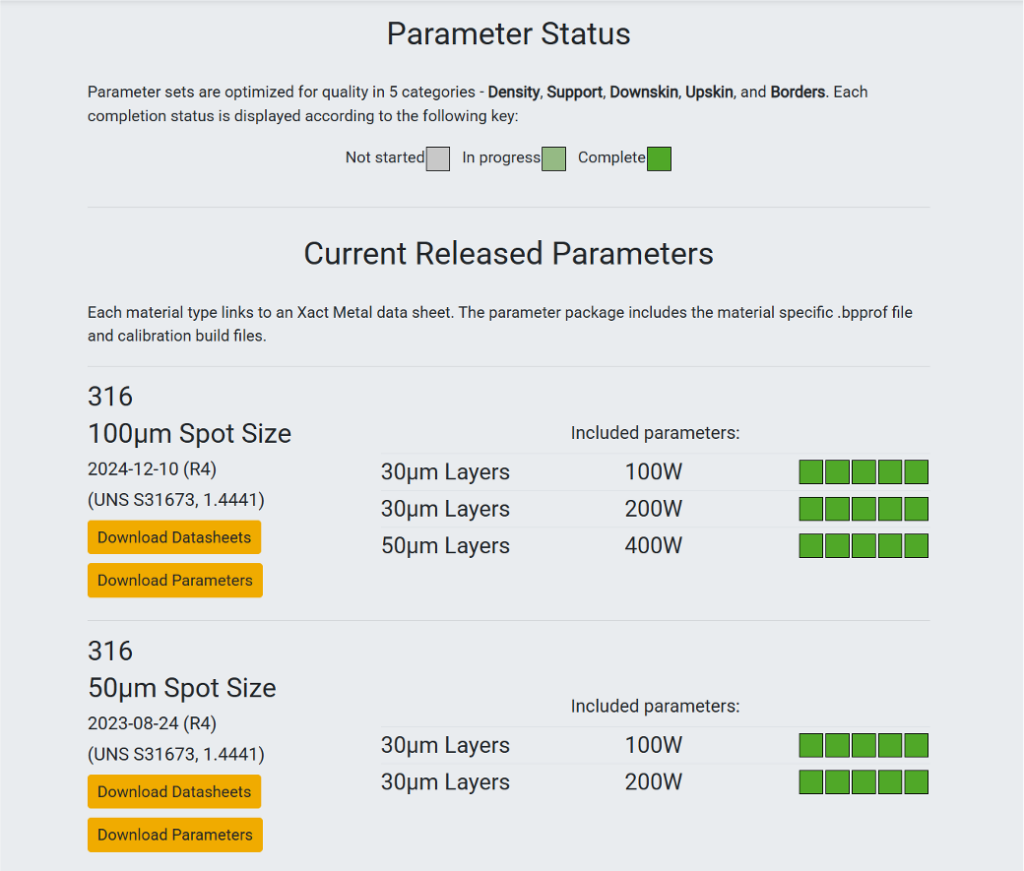

All exposure printing parameters for recommended powders are available at no-charge to our customers through a web-based application.

Parameters are available for various combinations of materials, laser power, spot size and layer thickness. Contact us for availability of specific parameters.

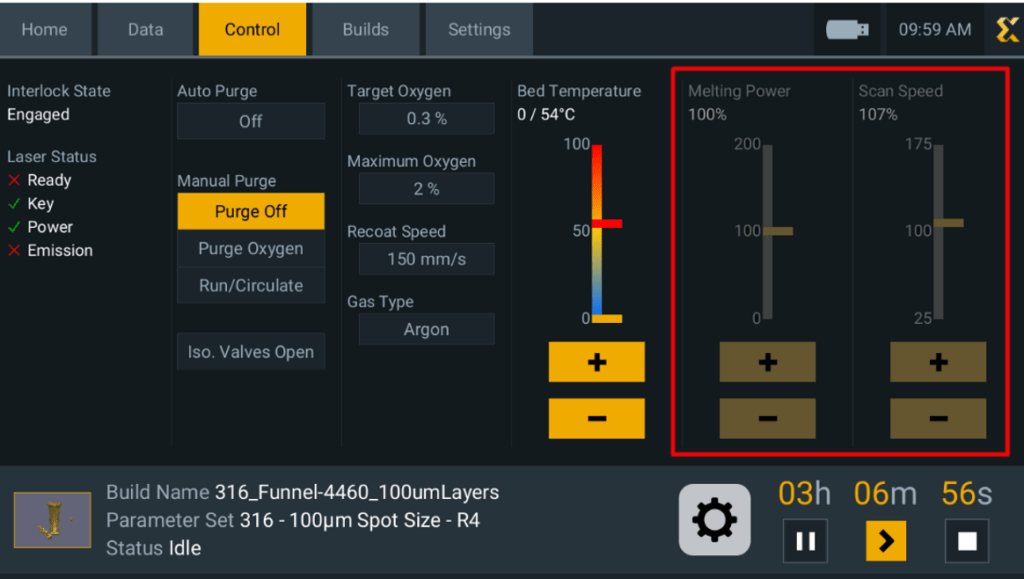

Open parameters give metal 3D printing experts direct access to the fundamental parameters of their printing process, including melting power, scan speed and recoating speed.

Advanced profile features are also available when combined with Materialise Magics or Oqton 3DXpert.