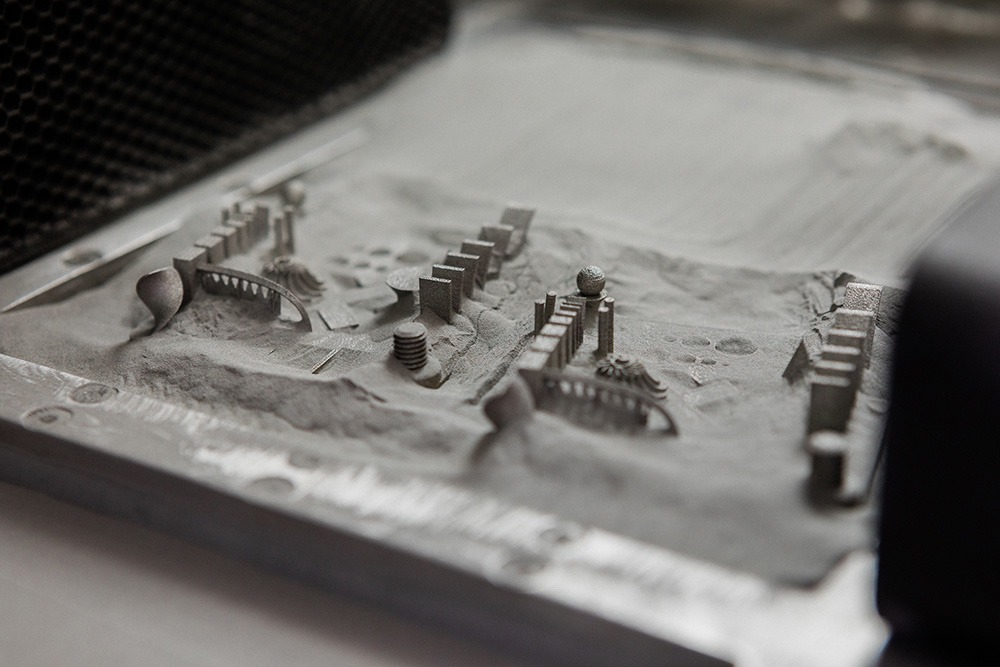

Xact Metal provides a wide range of metal powder materials to be used in powder-bed fusion printing. Optimal print parameters and control processes have been developed to ensure as-printed material performance.

Xact Metal partners with industry-leading powder producers, like Praxair Surface Technologies, to offer a wide range of high-quality, certified and proven metal powders. These gas-atomized powders ensure all layers print with consistent density and uniform build rates to deliver mechanical, performance, and final part specifications.

Xact Metal partners with industry leading powder producers, like Bego Medical, Carpenter Additive, and Praxair Surface technologies, to offer a wide range of high-quality, certified and proven metal powders. These gas-atomized powders ensure all layers print with consistent density and uniform build rates to deliver mechanical, performance, and final part specifications.

Our high-quality, gas-atomized metal powders are specifically designed for additive manufacturing to support every part you make with capacity, quality, and experience.

1.Only available on XM200G Series, 2. Availability of parameters available on request